Paige Bus™ Insulation Piercing Connector (IPC) Trunk Bus System

Paige’s Insulation Piercing Connector: Faster, easier, cleaner.

We started working with IPCs in 2015 and now have over 2.5 GW of legacy products in service. Our current IPC is field-tested, retrofits with other systems, and is modifiable to fit changing site conditions.

- Available in sizes 1/0-4/0, 350-500 KcMil, 600-750 KcMil, 1000 KcMil

- PTL-Listed certified to UL-9703

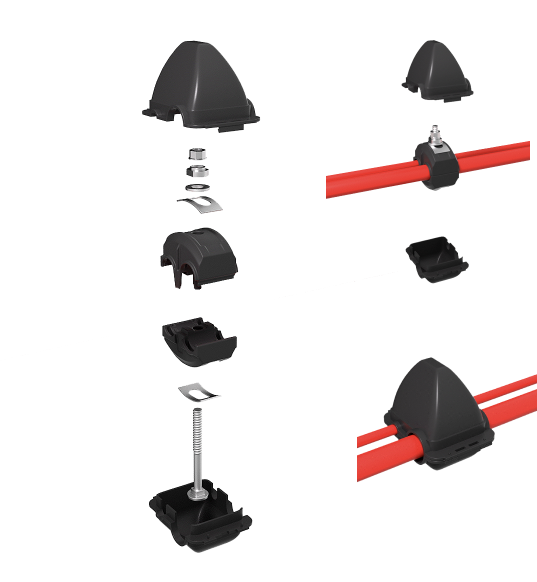

See how it works

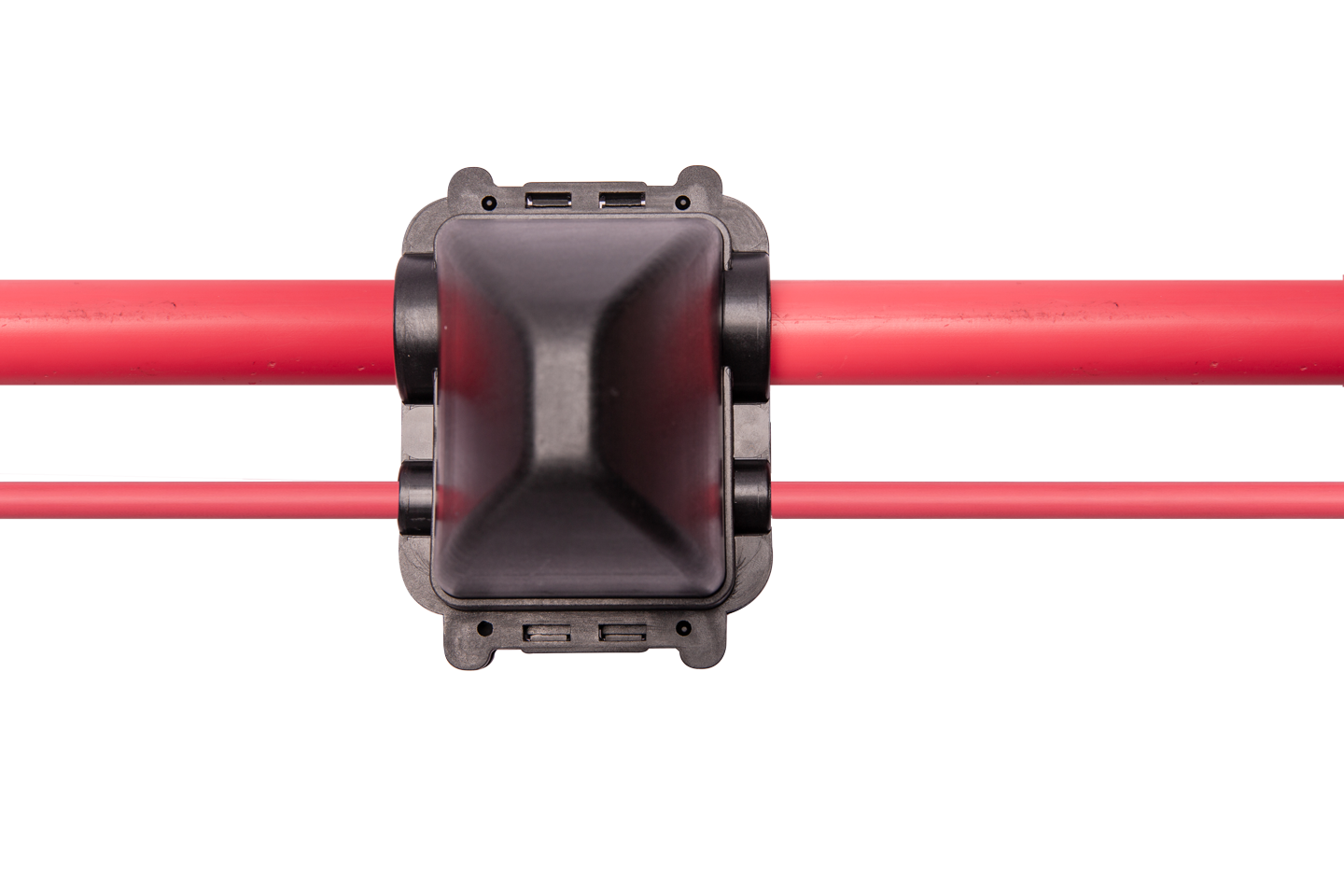

All material is high quality and installed on several GW’s worth of projects:

- Body and cover made from V0-rated material

- Teeth made of tinned copper

- Cover snaps on the outside to comply with testing requirements and protects against voltage creep

- Environmentally sealed piercing teeth feature a self-sealing close with no sticky gels

- Insulated shear bolt shears off once you reach the proper torque

Why UL-9703?

Because we won’t settle for status quo when it means giving you less than the best. We know you’re used to looking for UL 6703 or 486, but UL 9703 is the strongest standard available.

- UL 9703 has more aggressive testing requirements and is more difficult to secure

- That means passing a freezing test, thermal chamber test, wet high pot, impact testing and more. Put simply, 9703 means you’re getting the highest level of durability.

- Unlike 486, which was developed years ago and covers a broad range of connectors, 9703 was specifically developed for wiring harnesses used to interconnect distributed generation system devices.

- 9703-listed components must comply with 31 other UL standards.